In the late 1980's, Pierre Schwaar was a local legend around the Phoenix telescope

maker's community. His optics were exemplary and his stream of new, innovative

ideas could make NASA take notice. He was a force of nature among telescope

makers, coming up with a 16" F/5 "Telescope-Go-Round", the "Big

Foot" mount and his 8" F/4 Binocular Chair. He tinkered constantly,

ever refining and tweaking his inventions to work better and better.

While there was never a doubt of his mirror making abilities, there was some

about his mechanical skills. Some of his tinkering was due to necessity-fatally

flawed details in engineering on the path from his inventive mind and his limited

materials. While his workmanship was high in quality, the design phases were

somewhat limited. Plans went from his head to the cutting table or lathe, without

much consideration given to fine details.

This is so much the tragedy, since many parts from one project went to build

the next. Sometimes it worked, sometimes not.

I found this out in the first restoration of the BinoChair. I spent 5 years,

off and on, working on it, only to see the design flaws take their toll upon

completion. It was my intent then and there to do a complete structural analysis

of the system as a whole, and rebuild the chair to make it more user friendly.

The results of this redesign will be presented here. Click on images to enlarge.

Pierre's chair in ~1990.

My perception of improvements.

The main ideas were to

1) keep the center of mass within the rotation in altitude,

2) move the chair closer to the ground and

3) refine the drive system to work more smoothly.

4) anything else to make it work easier.

Solutions were,

1) make the pedestal wider,

2) improve the azimuth bearing and

3) widen the base for the chair's altitude bearing.

These drawings, (works in progress and amended as completed), reflect the

main ideas. The pedestal has been widened. The azimuth bearing has been replaced

with the wheel and spindle assembly from my old water hauling trailer. This

trailer successfully hauled a 525 gallon water tank weighing ~4 tons, typically

3 to 6 miles back and forth to the well over washboard dirt roads for nearly

3 years at ~35 mph before the welds to the axle broke, (not the wheel assembly

itself). I figure, it'll handle a human up to several hundred pounds, rotating

on a smooth surface at no more than 4 rpm. The altitude bearing has been made

of 1.25" thick plywood with a radius of ~24". The center of mass of

the chair, alt bearings, OTA and a human of 180lbs has been calculated and is

represented with a sphere visible at the center of rotation of the alt bearing.

Another sphere, representing the center of mass of the chair with a human sitting

in it is shown just behind the seat. A third sphere, representing the center

of mass of the OTA is shown in the OTA.

On to the new pictures. Much of the weekend of 11/24/07 (Thanksgiving here

in the States), was spent working on the pedestal and torsion box.

|

The basic base, showing the wheel mounted on 2x4's. |

|

From the underside. |

|

Detail shows screws, but glue was added later. |

|

Illustrating the PVC "feet" to be used at the corners. |

|

The (mostly) completed base unit. PVC feet are not yet attached, nor is

the ring for azimuth drive cable. |

|

Structure from underneath. |

|

Beginnings of the torsion box to support the chair and OTA. |

|

Good image showing the lower sheet of 3/4" playwood and the internal

structure that lends the torsion box its strength. The strips are glued

to the sheet, and glued to the top sheet, effectively connecting 25 smaller

boxes of plywood together, rendering them very very stiff, yet not very

thick. |

|

Bottom is glued and drying in the truck bed. |

|

Each piece was glued and stapled to the bottom sheet to maintain position. |

|

Bottom placed on pedestal assembly. |

|

Top sheet placed before gluing. |

|

Completed torsion box with rollers and steel brackets placed on top. |

|

Thin! Rosie and I stood on opposite sides after this dried over night.

We could detect no flexing or tilting at all. I weigh 213 lbs and she weighs...about

half that. :-) |

|

Close-up of the torsion box shows the staples and guide lines. |

Fighting problems with a shifting center of gravity, I decided

to rebuild the sides of the chair. The problems were

1) People are different.

2) The chair couldn't adapt to different conditions

3) The chair sides didn't have enough material to mount the

rail solution.

4) The chair sides also had too many holes in them.

Different people have different distributions of doffering amounts

of mass. As a more massive person sits in the chair, they shift the center of

mass of the whole system. This causes balance and altitude motor loading problems

as the load shifts. I came up with a couple solutions. One is to counter the

shift by adding weights to the backside of the alt bearings, but this requires

I carry many counterweights, and the whole idea was to avoid that. The one I

chose was to make the chair and OTA adjustable foreward and backward, to reposition

the center of rotation according to the weight of the occupant. I devised a

system of T-rails, with bolts through the alt bearings. Two parallel rails will

easily accommodate the load, but when I went to mount them on the chair, I found

there wasn't enough material there to support them both. I took the chair apart

to figure it out and, looking at the individual chair side and seeing all the

previous holes, I decided to build new ones with sufficient mounting materials

and consistant thickness.

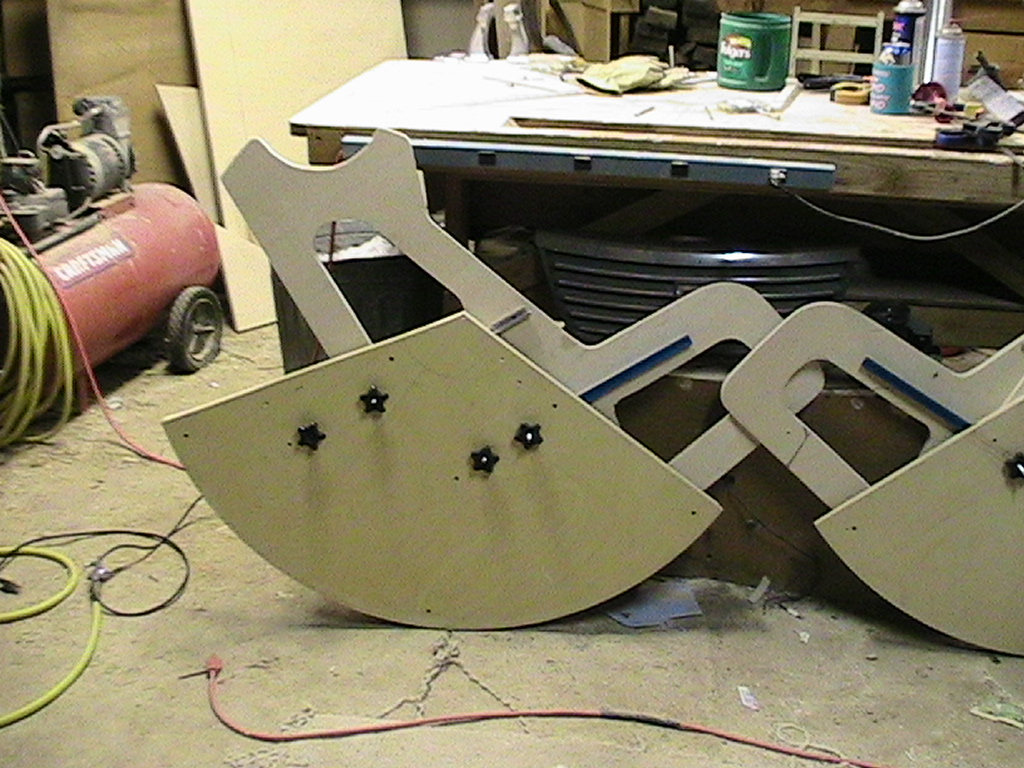

|

The new sides, side by side, ;-) showing the new bearings, the star-bolts

that mount to the rails and fasten the bearings to the chair sides. |

|

A little closer view of one new assembly. |

I'm extremely excited about the progress made so far. I need to work out how

powerful the motors have to be to drive this thing. I also need it to be damped

so it won't just slide one way or the other, so some form of clutch is in order.

It moves very, very easily in azimuth, and if the rollers were spaced properly,

it would move in altitude easily too. Before I got the rollers installed, I

placed the chair and alt bearings on the pedestal. It rocked like a rocking

chair-nice and easy and stayed put, even when spun in azimuth!

Page URL: http://www.stargazing.net/Astroman/ATM/NewChair.htm

Copyright 2007, Steve Dodder

Webmaster: Steve Dodder

Created: 12/3/07

Last modified 12/3/07

Page URL: http://www.stargazing.net/Astroman/ATM/NewChair.htm

Page URL: http://www.stargazing.net/Astroman/ATM/NewChair.htm